A specialized device designed to automatically remove the outer skin and core of pineapples, widely used in fruit processing plants, food manufacturing, catering industries, and pineapple deep-processing sectors. Below is a detailed breakdown of its features, technical specifications, applications, and market trends.

Multi-Process Integration

Modern machines combine peeling, coring, end-cutting (trimming head/tail), and even slicing into one system. For example, some models can process 500 pineapples/hour, completing all four steps automatically, boosting efficiency.

Adaptive Adjustment

Equipped with smart controls, the machine adjusts blade positions and peeling thickness (1.5–10mm adjustable) based on pineapple size (diameter 80–250mm, height 160–350mm).

Minimizes waste and ensures uniform processing.

High Efficiency & Stability

Capacity: Ranges from 6–12 pineapples/hour (small-scale) to 500 pineapples/hour (large-scale).

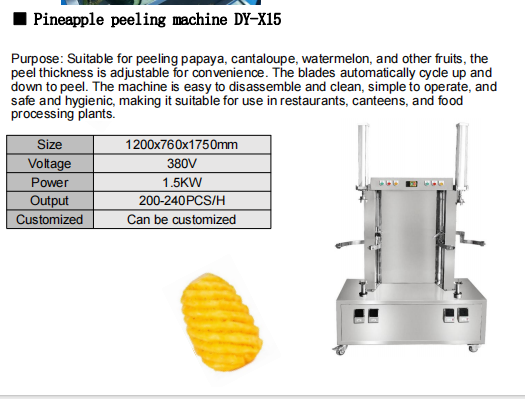

Power: 0.75KW–3.85KW, with voltage options of 220V/380V for industrial flexibility.

Design: Uses specialized scraping blades, high-speed rotating drums, and coring tools to ensure thorough peeling and core removal while reducing downtime.

User-Friendly Operation

Some models feature touchscreen interfaces, allowing operators to set parameters (e.g., peeling thickness, slice count) with one-click start, lowering technical barriers.

| Parameter | Typical Range/Example |

|---|---|

| Capacity | 6–500 pineapples/hour (model-dependent) |

| Fruit Diameter | 70–130mm (small) to 80–250mm (large) |

| Peeling Thickness | 1.5–10mm adjustable |

| Power | 0.75KW–3.85KW |

| Voltage | 220V/380V |

| Dimensions | 1200×700×1300mm (small) to 4700×1760×2050mm (large) |

| Blade Count | 4 blades (basic) to multi-blade sets (large models) |

Industrial Production

Canned Fruit: Processed cylindrical pineapple cores are ideal for canning, ensuring standardization.

Dried Fruit/Preserves: Uniformly peeled slices dry more evenly, improving product consistency.

Beverages: Pre-peeled pineapples simplify juicing or fruit-particle drink production.

Catering & Retail

Hotels/Restaurants: Rapidly processes large volumes for fresh fruit platters.

Supermarkets/Fruit Shops: Live demonstrations attract customers to buy whole or sliced pineapples.

Cold Chain & Deep Processing

Pre-processed pineapples are easier to package and transport, extending shelf life and reducing spoilage.

This structured overview highlights the pineapple peeling machine’s role in modernizing fruit processing while addressing efficiency, scalability, and market demands. Let me know if you need further refinements!