Industrial apple juicers typically adopt dual-screw continuous pressing technology or integrated crushing-pressing designs to maximize efficiency and juice yield:

Dual-Screw Continuous Pressing:

Conveyor Screw: Transports apple pulp into the pressing chamber.

Pressing Screw: Gradually reduces pitch and increases shaft diameter, combined with sieve wall and cone resistance, to extract juice through screen holes.

Residue Discharge: Adjusts spring preload and cone position to control residue dryness and optimize juice extraction.

Integrated Crushing-Pressing:

Some models (e.g., automatic apple juicers) integrate crushing units to process whole apples directly. The spiral extrusion mechanism breaks fruit, then presses juice via reducing chamber volume and increasing sieve resistance.

Industrial apple juicers are categorized by capacity and design:

| Type | Capacity | Power | Dimensions | Feeding System | Applications |

|---|---|---|---|---|---|

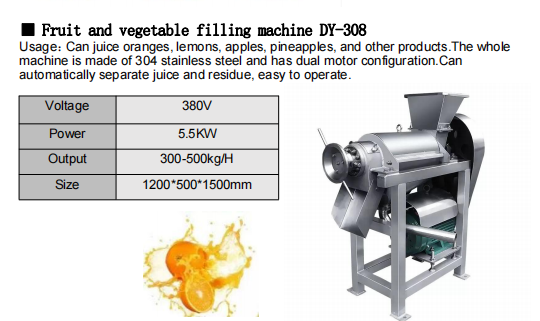

| Small-Scale | 0.5–1.5 tons/hour | 1.5–5.5 kW | 780×320×860 mm | Single inlet | SME juice plants, catering |

| Medium-Scale | 2.5–5 tons/hour | 15–30 kW | 1600×700×1760 mm | Multi-inlet | Large factories, food processing |

| Fully Automated Line | 500 apples/hour (~2.5 tons) | 11.2 kW | 1850×1200×2650 mm | Crushing + pressing + residue discharge | Mass production, deep processing |

Key Parameters:

Power: Ranges from 1.5 kW (small-scale) to 30 kW (medium-scale).

Dimensions: Vary by capacity (e.g., 0.78 m³ for small models vs. 1.85 m³ for automated lines).

Feeding: Some support bulk hoppers (15–20 apples/batch) to reduce manual labor.

Select based on production volume. For example:

SMEs: 0.5–1.5 tons/hour (e.g., 15 kW medium-scale machine).

Large Enterprises: 2.5–5 tons/hour (fully automated lines).

Data: A fully automated line processes 500 apples/minute (~2.5 tons/hour).

Prioritize slow-extrusion or dual-screw pressing for higher yield and minimal oxidation.

Example: Adjusting cone spring preload optimizes residue dryness and juice extraction efficiency.

Choose models with detachable parts and easy-clean designs (e.g., stainless steel sieves).

Feature: Fully enclosed systems with safety interlocks comply with hygiene standards.

Core components (screws, sieves) should be stainless steel for corrosion resistance.

Example: Spiral extrusion parts in some models withstand 24-hour continuous operation.

Cost-Effective: Medium-scale machines (15 kW, 2.5 tons/hour) for SMEs.

Premium: Fully automated lines from reputable brands (customizable for deep processing).