The control panel of the Fish Slicer Machine is a model of professional equipment. It abandons the complex and cumbersome operation modes of traditional machines and adopts a simple and intuitive design concept. Operators do not need to possess professional technical knowledge; a short training session is enough for them to get the hang of it easily. The various function buttons on the panel are reasonably arranged and clearly labeled. Operators can quickly complete various operation commands with just a light press, greatly saving operation time and energy and improving overall work efficiency.

Safety is the core element of enterprise production, and this fish slicer's control panel excels in safety performance. It has excellent waterproof capabilities, employing advanced sealing technology to effectively prevent moisture from seeping into the internal circuits. Even in humid processing environments, it can ensure the normal operation of the equipment, avoiding safety accidents caused by short circuits. At the same time, it also features a reliable anti-leakage design, with multiple safety protection mechanisms providing solid safeguards for the personal safety of operators. Operators do not need to worry about the risk of electric shock during use and can devote themselves wholeheartedly to work, creating more value for the enterprise.

In the process of fish processing, the cutting speed directly affects production efficiency and output. The dual-bin inlet design of the Fish Slicer Machine provides strong support for high-efficiency processing. This unique design breaks the limitations of traditional single-bin inlets and enables dual-channel simultaneous feeding. Operators can place two fish or more ingredients into the two inlet bins at the same time, and the equipment can quickly and stably send the ingredients into the cutting area for slicing.

Compared with single-bin inlets, the dual-bin inlet significantly shortens the feeding time and reduces waiting intervals, making the cutting process more continuous and smooth. In actual production, using this fish slicer, the cutting speed has been greatly improved, and more slicing tasks can be completed in a shorter time. For example, within the same working hours, a traditional slicer may only be able to process a certain number of fish, while the Fish Slicer Machine, with its dual-bin inlet design, can process double or even more fish, saving a large amount of time and labor costs for the enterprise and improving overall production efficiency to meet the needs of large-scale commercial processing.

The cutting blade is the core component of a fish slicer, and its quality directly affects the slicing effect and the service life of the equipment. The Fish Slicer Machine uses high-quality 440 material to forge the cutting blade, which has many excellent properties.

The 440 material has high hardness and wear resistance. During the cutting process, it can easily handle the bones and tough flesh tissues of various fish, ensuring uniform cutting and flat cuts. Each piece of fish can be precisely sliced into the required thickness and shape, ensuring the consistency and stability of the slicing quality and providing a good foundation for subsequent processing and cooking. Whether it is for making sashimi, baked fish slices, or fried fish fillets, it can meet the high requirements for slicing quality and enhance the market competitiveness of the products.

At the same time, the 440 material also has good toughness and is not prone to breakage or deformation. During long-term and high-intensity use, the cutting blade can maintain stable performance, reducing the downtime for equipment maintenance caused by blade damage and improving the utilization rate of the equipment. Moreover, this material makes the blade highly durable and has a long service life. Enterprises do not need to frequently replace the blade, reducing the equipment's usage and maintenance costs and saving a significant amount of capital investment for the enterprise.

Different dishes have different requirements for the thickness of fish slices. The Fish Slicer Machine fully takes this into account and offers an adjustable slicing thickness range of 1.5 - 10mm. Operators can easily adjust the slicing thickness according to specific processing needs and ingredient characteristics.

If thin sashimi is required, simply adjust the slicing thickness to a thinner setting, and the equipment can precisely cut out uniform thin slices, making the sashimi more visually appealing and the taste fresher and more tender. For baked fish slices or fried fish fillets that require a certain thickness, operators can adjust the slicing thickness to a thicker setting to ensure that the slices maintain their complete shape during cooking, locking in moisture and nutrients and making the dishes more delicious.

This flexible slicing thickness adjustment function enables the Fish Slicer Machine to adapt to a variety of processing scenarios and dish requirements, providing enterprises with more processing options and product innovation space. Enterprises can develop a wider range of fish products based on market demand and consumer preferences, meeting the needs of different customer groups and enhancing the enterprise's market adaptability and competitiveness.

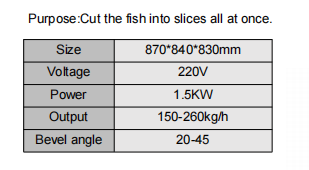

The Fish Slicer Machine, with its easy-to-operate and safe control panel, high-efficiency dual-bin inlet design, high-quality and durable cutting blade, and adjustable slicing thickness, has become an ideal choice for fish processing enterprises. It can not only significantly improve production efficiency and product quality but also reduce usage and maintenance costs for enterprises, helping them stand out in the fierce market competition and achieve sustainable development. Choosing the Fish Slicer Machine is choosing an efficient, high-quality, and safe fish processing solution.