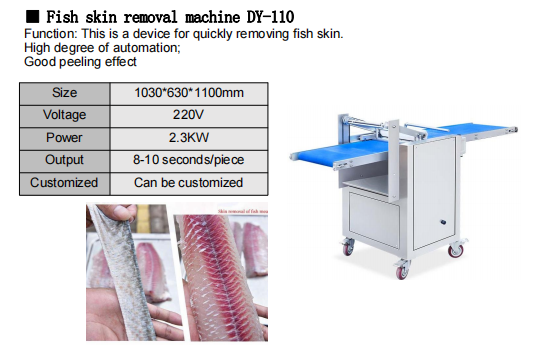

Designed for fish processors, supermarkets, and commercial kitchens, our Fish Skinning Machine automates the removal of fish skin with high speed, accuracy, and minimal waste. Ideal for frozen, fresh, or cooked fish fillets, it enhances productivity while maintaining food safety standards.

High-Speed Performance

Processes up to 50 fillets per minute (e.g., DY-110), boosting output by 300% compared to manual labor.

Automated feeding and skinning reduce downtime and labor costs.

Universal Compatibility

Handles a wide range of fish species, including squid, catfish, cod, carp, tilapia, and salmon.

Adjustable settings accommodate varying fillet sizes (e.g., 10–300g) and thicknesses.

Precision Skin Removal

Advanced blade technology ensures 99% skin removal rate with minimal flesh waste.

Customizable cutting depth (0.5–10mm) to preserve meat quality.

Hygienic & Durable Design

Constructed with 304 stainless steel for corrosion resistance and easy sanitization.

Food-grade components comply with international safety standards (e.g., CE, FDA).

User-Friendly Operation

Intuitive touchscreen interface with preset programs for common fish types.

Automatic lubrication and self-cleaning systems simplify maintenance.

Capacity: 50 fillets/min (adjustable speed)

Power: 2.2 kW (electric)

Voltage: 220V 50Hz

Dimensions: 1030 × 630 × 1100 mm

Weight: 280 kg

Fish Processing Plants: For bulk skinning of frozen/fresh fillets.

Supermarkets & Retail: Pre-processed fillets for ready-to-cook sections.

Restaurants & Catering: Consistent quality for sushi, grilled fish, or fried dishes.

Cost-Effective: Reduces labor by 70% and material waste by 15%.

Reliability: Proven in high-volume environments with 24/7 operation capability.

Customization: Optional accessories for deboning, trimming, or portioning.