Model: [Customizable]

Voltage: 380V (Industrial Standard)

Total Motor Power: 1.9 kW

Dimensions: 1587 × 817 × 1260 mm (L × W × H)

Belt Length: 2.6 meters

Material: Full 304 Stainless Steel (Food-Grade, HACCP Compliant)

Blade Specifications:

Main Deboning Blade: 350mm × 3mm (Diameter × Thickness)

Abdominal Blade: 200mm × 3mm (Diameter × Thickness)

Efficiency: 20–40 fish/minute (Depending on fish size)

Applicable Fish Species: Snakehead , Grass Carp , Sea Bass , Qingjiang Fish , Bighead Carp , etc.

High Precision & Yield

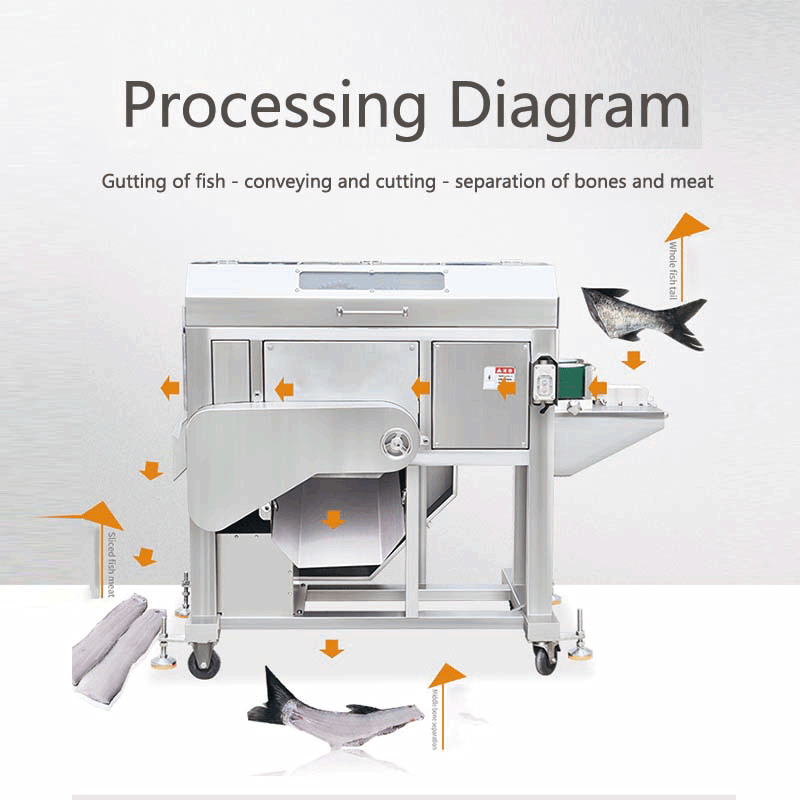

Triple-Cut Design: Splits fish into three sections—removes central backbone while preserving bilateral fillets with minimal waste.

Optimized Blade Geometry: Specialized stainless steel blades (350mm/200mm) ensure clean cuts, reducing meat adhesion and improving yield by up to 95%.

Durable & Hygienic

304 Stainless Steel Construction: Resists corrosion, meets food safety standards, and simplifies cleaning.

Rust-Resistant Blades: Hardened stainless steel with anti-corrosion coating for long-term durability.

Versatile Processing

Handles Fresh & Partially Thawed Fish: Adapts to varying temperatures (-2°C to 10°C) without compromising cut quality.

Customizable Settings: Adjustable blade pressure and speed for different fish sizes (e.g., 300g–2kg per fish).

Efficient Operation

Throughput: Processes 1,200–2,400 fish/hour (20–40 fish/min), ideal for high-volume production.

Low Maintenance: Modular design with tool-free blade replacement and self-lubricating bearings.

| Parameter | Detail |

|---|---|

| Power Supply | 380V 3-Phase |

| Motor Type | Brushless DC (Energy-Efficient) |

| Blade Speed | 1,200–1,500 RPM (Adjustable) |

| Noise Level | <65 db=""> |

| Weight | Approx. 380 kg |

Food Processing Plants: Surimi production, fish balls, fish cakes, and frozen fillets.

Restaurants/Catering: Centralized prep for high-volume kitchens.

Aquaculture Farms: On-site processing to reduce transportation costs.

✅ Higher Yield: 5–10% more meat recovery vs. traditional methods.

✅ Reduced Labor: Replaces 3–5 manual workers, cutting labor costs by 60%.

✅ Flexibility: Processes diverse species (freshwater/marine) and sizes.

Conveyor Integration: Automated feeding system for continuous operation.

PLC Control Panel: Precision adjustment via touchscreen (e.g., blade pressure, speed).

Waste Collection System: Separates bones/skins for byproduct utilization (e.g., fishmeal).

Proven Performance: Deployed in factories across China, Southeast Asia, and Europe.

ROI: Pays back investment in 8–14 months through labor savings and yield improvement.

Support: 24/7 technical assistance and spare parts supply.