A commercial meatball forming machine is an automated food processing equipment designed to efficiently produce uniformly shaped, smooth-surfaced meatballs for large-scale operations. It supports various meatball types and is ideal for restaurants, food factories, supermarkets, and catering businesses.

High Production Capacity

Advanced models can produce up to 120,000 meatballs per hour, meeting bulk demands.

Entry-level machines (e.g., VEVOR) offer 280–300 meatballs per minute, boosting productivity significantly.

Versatile Size & Type Customization

Adjustable diameter range: 12–35mm, with some models offering 6 size options (e.g., 18mm, 22mm, 26mm).

Supports both solid meatballs (beef, pork) and stuffed variants (e.g., cheese-filled chicken meatballs), with adjustable filling volume.

Food-Grade Materials & Hygiene

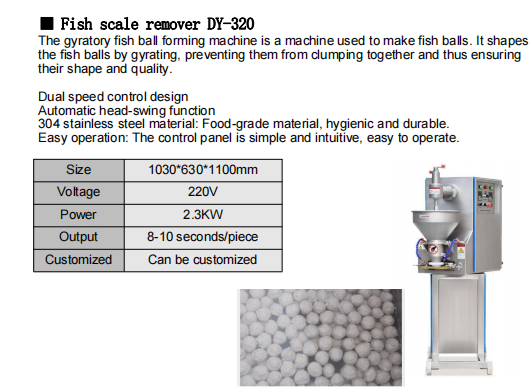

Constructed with stainless steel for durability and easy cleaning, complying with food safety standards.

Thoughtful design features, such as lubrication points, extend machine lifespan and reduce maintenance costs.

User-Friendly Operation

Equipped with intuitive control panels, requiring minimal training.

Some models include mobile wheels for flexible placement in kitchens or factories.

Foodservice Industry: Hot pot restaurants, fast-food chains, hotels, and caterers needing high-volume meatball supply.

Food Processing Plants: Manufacturers of frozen meatballs, ready-to-cook meals, and预制菜 (prepared dishes).

Retail & Markets: Supermarket fresh sections or deli counters offering on-site meatball production.

Specs: 110V, 1100W, 280–300 meatballs/min, size options: 18/22/26/28/30/32mm.

Strengths: Cost-effective, suitable for SMBs; stainless steel body, mobile design, easy operation.

User Feedback: Praised for efficiency and reliability in boosting production capacity.

Specs: 220V, 1.1kW, 200 meatballs/min, size options: 17/22/24/27mm.

Strengths: Precision-sized meatballs; durable stainless steel bucket and gear shaft, low maintenance.

User Feedback: Highly stable for long-term heavy-duty use.

Specs: Up to 120,000 stuffed meatballs/hour, customizable fillings (vegetables, seafood).

Strengths: Ideal for large factories producing complex meatballs; fully automated for scalability.

Consideration: Higher upfront cost but offers unmatched productivity for industrial use.

Production Needs: Match machine capacity to your business scale to avoid over/underinvestment.

Size Flexibility: Prioritize adjustable molds if diverse meatball sizes are required.

Budget & ROI: Entry-level models (e.g., VEVOR) suit startups, while high-end machines justify costs for large-scale operations.

After-Sales Support: Choose brands offering technical assistance and spare parts availability to minimize downtime.

This guide equips you with the insights to select the right commercial meatball forming machine for your business, balancing efficiency, cost, and quality. For further inquiries, consult suppliers or request product demos to test performance firsthand.