Model: [Customizable]

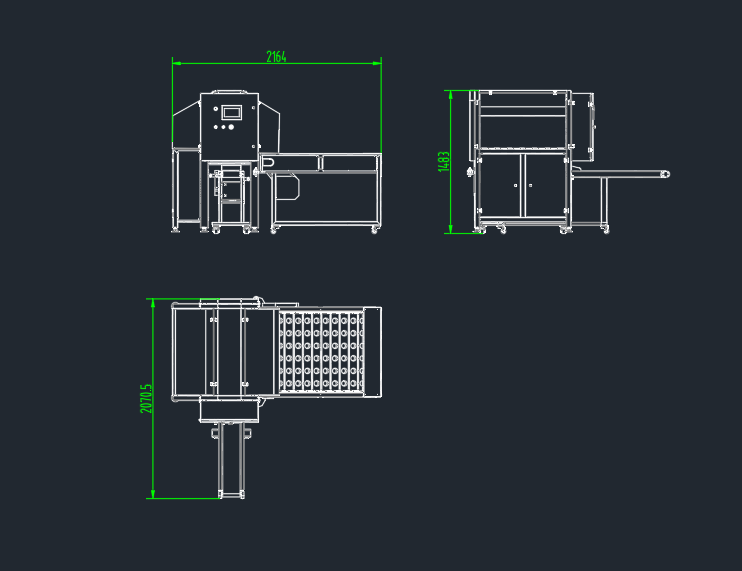

Dimensions: 2164 × 2000 × 1483 mm (L × W × H)

Power: 1.8 kW (Industrial Grade)

Voltage: 380V (Customizable to 220V for specific applications)

Material: Full 304 Stainless Steel Construction (Food-Grade, Corrosion-Resistant)

Cutting Customization: Adjustable Slice Thickness (3mm–20mm) & Dicing Options (Via Optional Blade Sets)

High-Efficiency Processing

Capable of slicing 500–1000 kg/hour (varies by fruit type and slice size).

Suitable for tomatoes, lemons, apples, oranges, and other soft/firm fruits.

Precision & Uniformity

Dual-blade system ensures consistent thickness with minimal waste.

Optional dicing attachments for cube cuts (e.g., 10mm × 10mm).

Hygiene & Durability

Full 304 stainless steel body resists rust and meets food safety standards (FDA/EU compliant).

Rounded edges and tool-free disassembly for easy cleaning.

Industrial-Grade Design

Heavy-duty motor (1.8 kW) supports continuous operation.

Reinforced frame reduces vibration during high-speed slicing.

Food Processing Factories: Tomato sauce, dried lemon slices, apple pie filling.

Commercial Kitchens: Centralized prep for restaurants, hotels, and catering services.

Agricultural Export: Standardized slicing for frozen fruit packs or canned goods.

| Parameter | Detail |

|---|---|

| Power Supply | 380V 3-Phase (Customizable) |

| Blade Speed | 1,450 RPM (Adjustable) |

| Feed Inlet | 200 × 150 mm (Accepts whole fruits) |

| Noise Level | <70 dB (Industrial Standard) |

| Weight | Approx. 450 kg |

✅ Cost-Effective: Replaces 5–8 manual laborers, with ROI in 1–2 years.

✅ Flexible: Adapts to multiple fruits and cutting styles.

✅ Reliable: Proven in factories across Europe and Asia.

Conveyor Belt System: For automated feeding.

PLC Control Panel: Precision adjustment via touchscreen.

Waste Collection Tray: Separates peels/cores for composting.