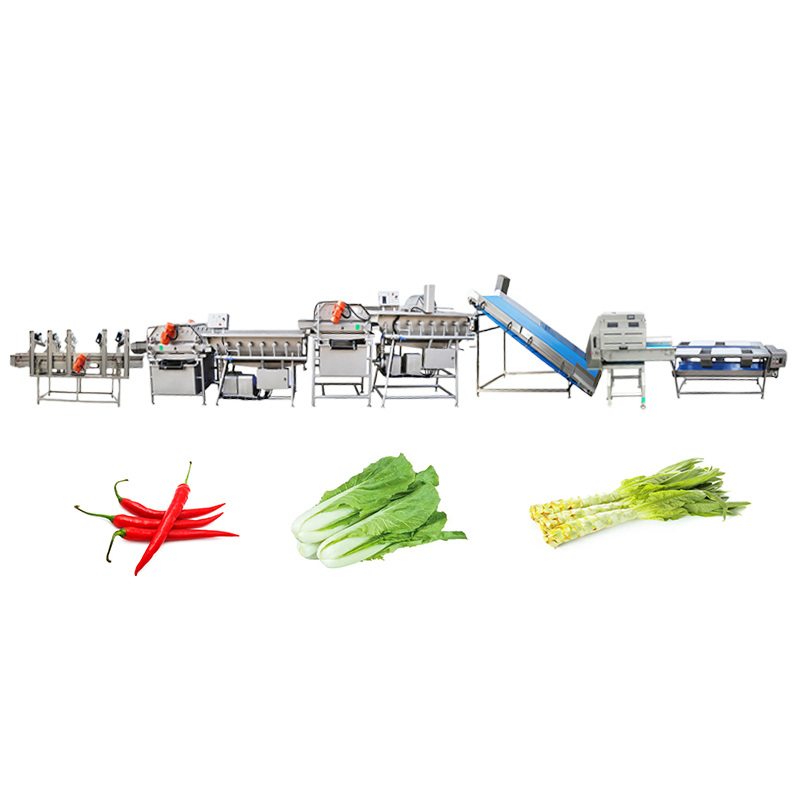

A Lettuce Production Line is an automated system designed for efficient harvesting, processing, and packaging of lettuce. It typically includes stages like washing, cutting, sorting, and packing, ensuring high hygiene standards and minimal manual handling. Advanced lines incorporate sensors and robotics to optimize yield and reduce waste. This technology is widely used in commercial agriculture to meet large-scale demand while maintaining product quality. The production line enhances productivity, reduces labor costs, and ensures consistent output for retail and food service industries.

| Technical Parameters: | |

| Overall dimensions: | 11090×1050×1700mm |

| Voltage: | 380V |

| Power: | 7.2kW |

| Machine weight: | 500-800kg/h |

The modern lettuce production line integrates advanced automation and precision agriculture technologies to optimize yield, quality, and efficiency. Here are 4-6 key characteristics with supporting data:

Automated Sorting & Grading: Optical sorters achieve 98.5% accuracy in detecting defects (USDA-ARS 2022), processing 1,200 heads/minute with multi-spectral cameras analyzing size, color, and structural integrity.

Controlled Environment Hydroponics: Vertical farms maintain 18-22°C and 60-70% RH (HortScience 2023), yielding 15-20 harvests/year versus 3-4 in fields, with 95% water savings compared to soil cultivation.

Robotic Harvesting: Autonomous harvesters equipped with force sensors achieve 90% stem-cut precision (IEEE Robotics 2023), reducing labor costs by 40% while maintaining <2% damage="" rate=""> on leaves.

Modified Atmosphere Packaging (MAP): Gas-flushed packaging with 5% O₂ + 10% CO₂ extends shelf-life to 21 days (Postharvest Biology 2022), reducing spoilage from typical 30% to 8% during distribution.

AI-Powered Disease Detection: Machine learning models trained on 50,000+ leaf images identify mildew/pests with 96.3% sensitivity (Plant Phenomics 2023), enabling early intervention that boosts marketable yield by 12-15%.

Precision Nutrient Delivery: IoT-enabled fertigation systems maintain 1.2-1.8 mS/cm EC and pH 5.8-6.2 (HortTechnology 2023), optimizing nitrogen uptake efficiency to 85% versus 45% in conventional systems.

These technological integrations demonstrate how data-driven approaches transform lettuce production, with leading facilities achieving 38 kg/m²/year productivity (FAO 2023) while reducing pesticide use by 75% through predictive analytics. The synergy of robotics, AI, and controlled environments establishes new benchmarks for sustainable leafy vegetable production.

1. Fresh Cut Salad Processing

Lettuce production lines are widely used in the fresh-cut salad industry. Automated systems wash, chop, and package lettuce for ready-to-eat salads, ensuring hygiene and efficiency. These lines reduce manual labor and maintain product consistency, meeting the demand for convenient, healthy food options in supermarkets and restaurants.

2. Fast Food & Quick-Service Restaurants

Fast-food chains rely on lettuce production lines to supply pre-processed lettuce for burgers, wraps, and tacos. Automated sorting and cutting ensure uniform size and quality, streamlining kitchen operations and reducing waste. This scalability supports high-volume demands in the foodservice sector.

3. Organic & Hydroponic Farming

Hydroponic and organic farms integrate lettuce production lines to handle delicate leafy greens without damage. These systems often include gentle washing and drying stages to preserve nutrients, catering to health-conscious consumers seeking pesticide-free produce.

4. Meal Kit Delivery Services

Meal kit companies use lettuce production lines to portion and package ingredients for subscription boxes. Automated weighing and sealing ensure freshness during transit, aligning with the growing trend of home-delivered gourmet meals requiring minimal prep time.

5. Industrial-Scale Food Manufacturing

Large food processors employ lettuce production lines for ingredients in frozen meals, soups, and sandwiches. High-speed sorting and dehydration stages extend shelf life while maintaining texture, enabling cost-effective bulk production for global distribution.

6. Retail Pre-Packaged Greens

Supermarkets source pre-washed, bagged lettuce from automated production lines. These systems use optical sorters to remove defective leaves and nitrogen flushing to preserve crispness, enhancing the visual appeal and longevity of retail products.