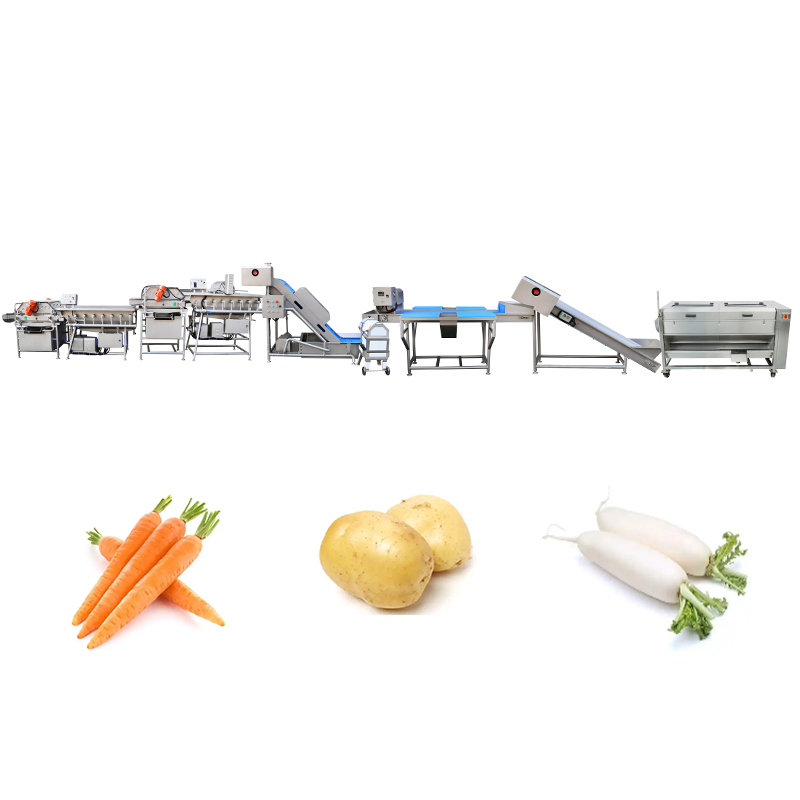

A Potato Production Line is an industrial system designed to automate the preparation and processing of potatoes into various products, such as fries, chips, starch, or dehydrated flakes. It typically includes equipment for washing, peeling, sorting, cutting, blanching, drying, frying (if applicable), and packaging. These lines enhance efficiency, reduce labor costs, and ensure consistent product quality. Advanced models may incorporate AI-driven sorting, waste recycling, and energy-saving features. Suitable for large-scale food production, potato processing lines cater to manufacturers seeking high throughput and compliance with food safety standards like ISO or HACCP.

A modern Potato Production Line is designed to maximize efficiency, quality, and yield while meeting industry standards. Below are 4-6 key features with technical specifications:

High-Capacity Washing System: Equipped with brush rollers and high-pressure water jets (15-20 bar), the system removes 98-99% of soil and debris. Advanced lines process 10-15 tons/hour with water recycling mechanisms reducing consumption by 30%.

Precision Peeling Technology: Steam or abrasive peelers achieve 90-95% peeling efficiency with minimal flesh loss (<5%). some="" systems="" integrate="" laser-guided="" peelers="" for="" irregularly="" shaped="" potatoes="">

Automated Sorting & Grading: Optical sorters with CCD cameras and AI algorithms inspect 40-60 potatoes/second, detecting defects (sprouts, greening) with 99.5% accuracy. Weight-based graders categorize tubers into 5-7 size groups at 8-12 tons/hour capacity.

Continuous Blanching System: Multi-zone blanchers maintain precise temperature control (70-85°C) with adjustable dwell times (2-8 minutes). This ensures uniform starch gelatinization while reducing sugar content by 15-20%, critical for chip production.

Energy-Efficient Drying: Multi-stage air knife dryers achieve moisture reduction from 80% to 10-12% in 15-20 minutes. Heat recovery systems cut energy use by 25%, with gas consumption as low as 0.8-1.2 kWh per ton of product.

Integrated Packaging (optional): Automated weighers and bagging machines handle 60-80 packs/minute with ±1g precision. Modified atmosphere packaging (MAP) extends shelf life to 90-120 days by maintaining 20% CO2 and 80% N2 gas mixtures.

These systems often comply with ISO 22000 and HACCP standards, featuring PLC-controlled operations with<5% downtime.="" the="" combination="" of="" throughput="">

1. French Fry Production

Potato processing lines are widely used in the large-scale manufacturing of French fries. The automated system washes, peels, cuts, blanches, and fries potatoes into uniform strips, ensuring consistency for fast-food chains and frozen food suppliers. Advanced fry-cutting technology minimizes waste and maximizes yield.

2. Potato Chips & Crisps

For snack manufacturers, these lines enable high-volume production of potato chips. Precision slicing (adjustable thickness), oil frying, seasoning application, and packaging integration allow for continuous output of crispy products with customized flavors and textures.

3. Dehydrated Potato Products

Processing lines convert potatoes into flakes, granules, or starch through cooking, mashing, and drying. These ingredients are essential for instant mashed potatoes, bakery mixes, and gluten-free food industries, offering extended shelf life and easy reconstitution.

4. Pre-Peeled & Fresh-Cut Potatoes

Restaurants and catering services rely on processing lines for washed, peeled, and vacuum-packed potatoes, reducing kitchen prep time. Modified atmosphere packaging (MAP) preserves freshness, while optical sorters remove defects for premium-grade products.

5. Potato-Based Animal Feed

Lower-grade potatoes or byproducts (peels, trimmings) are processed into nutritious livestock feed. Lines incorporate grinding, mixing, and pelleting to create balanced feed formulations, supporting sustainable agriculture practices.

6. Specialty Potato Snacks

Innovative lines produce curled, lattice-cut, or shaped potato snacks using specialized cutting dies. Coupled with multi-zone frying or baking systems, they cater to niche markets demanding unique textures and artisanal appeal.