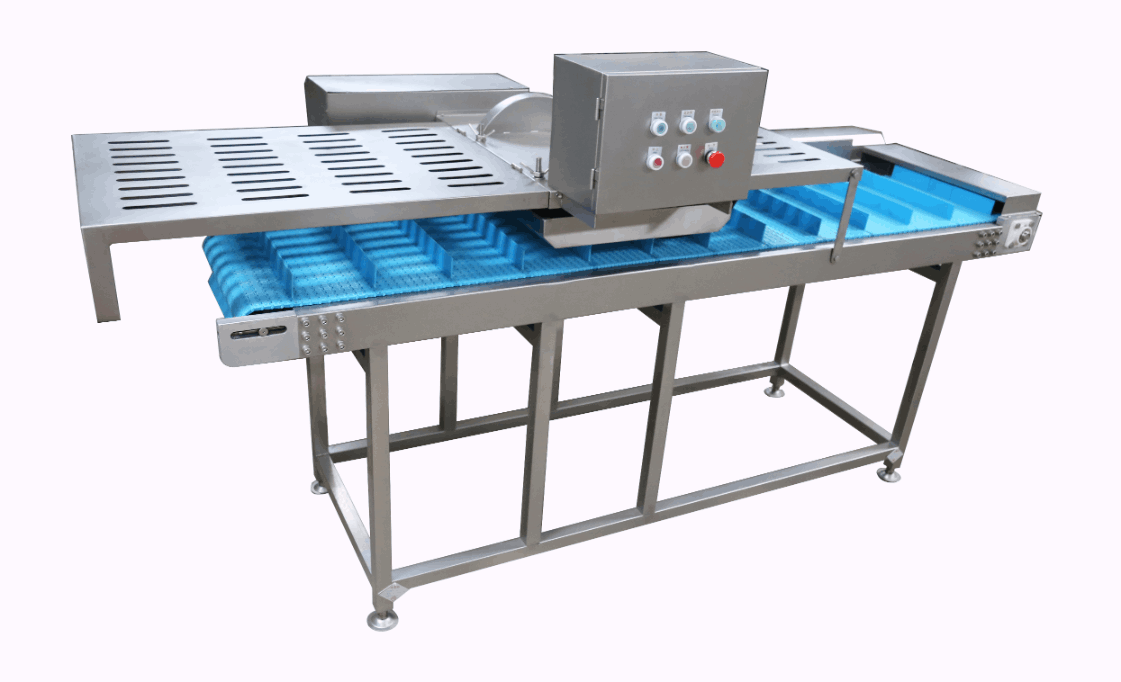

Used for root removal of vegetables, such as Shanghai greens, celery, spinach, chives and other vegetables.

Principle: The conveyor plate drives the material forward. After the vegetables pass through the fixed position of the knife disc, the roots of the vegetables are cut and discharged from the waste outlet, and the retained vegetables are conveyed forward.

Features:

--The whole machine is made of 304 stainless steel

--The cutting length can be customized, and the waste cut from each vegetable is equal

--Suitable for large food processing plants, clean vegetable production lines, etc.

| Technical Parameters: | |

| Overall dimensions: | 2600×1010×1230mm |

| Voltage: | 380V |

| Power: | 1.5kW |

| Production: | 2000-3000kg/h |

| Root removal length: | adjustable within 55mm |

Advantages:

This equipment can remove the roots of vegetables efficiently and quickly, maintain the integrity and appearance of vegetables, significantly reduce labor costs and improve production efficiency. It is suitable for various root vegetables, such as carrots, potatoes and beets, is easy to operate and meets hygiene and safety standards, effectively reduces food waste, and is an indispensable key equipment in the modern vegetable processing industry.

Vegetable Root Removal Machine is widely used in the field of vegetable processing. Its main advantages include efficient and rapid removal of the roots of various root vegetables, maintaining the integrity and beautiful appearance of the vegetables, significantly reducing labor costs and improving production efficiency. It is suitable for a variety of vegetables such as carrots, potatoes, beetroots, etc. It is easy to operate and meets hygiene and safety standards, effectively reducing food waste, and is an indispensable and important equipment in the vegetable processing industry.

The Vegetable Root Removal Machine is an advanced agricultural equipment designed to streamline the post-harvest processing of root vegetables. Here are 4-6 key features with technical specifications:

1. High-Efficiency Root Cutting System: Equipped with dual stainless steel blades rotating at 800-1200 RPM, the machine achieves a 98.5% root removal accuracy rate while processing 2-3 tons of vegetables per hour. The blade gap is adjustable from 0.5mm to 5mm to accommodate different vegetable sizes.

2. Intelligent Vibration Sorting: Features a 3-layer vibrating screen with amplitude of 5-8mm and frequency of 10-15Hz, effectively separating roots from vegetables with 95% purity. The vibration intensity can be precisely controlled through a digital panel.

3. Automated Conveyor System: The 4-meter long food-grade rubber conveyor belt operates at variable speeds of 0.2-0.5m/s, featuring anti-slip grooves and a loading capacity of 150kg/m². The system includes automatic alignment sensors with ±2mm positioning accuracy.

4. Energy-Saving Design: Powered by a 7.5kW three-phase motor with IE3 efficiency rating, the machine consumes only 0.15-0.2kWh per ton processed. The optimized gearbox reduces energy loss by 25% compared to conventional models.

5. Durable Construction: The main frame uses 304 stainless steel (2mm thickness) with IP54 protection rating. Critical components feature tungsten carbide coatings with hardness of 89-93 HRA, ensuring 10,000+ hours of operation life.

6. Smart Control System: Incorporates a PLC with 16-bit processing and 8-inch touchscreen interface. The system monitors performance in real-time with sensors providing data on throughput (accuracy ±3%), power consumption, and maintenance alerts.

Vegetable Root Removal Machine: 6 Key Application Fields

1. Commercial Food Processing Plants

Industrial-scale vegetable processing facilities utilize root removal machines to automate carrot, radish, and beet preparation. The machinery ensures consistent product quality while reducing labor costs by 40-60% compared to manual processing.

2. Agricultural Cooperatives

Farmer collectives employ these machines for post-harvest handling of root vegetables. The technology helps smallholders meet supermarket quality standards by delivering uniformly trimmed produce with minimal soil residue.

3. Frozen Food Manufacturing

In frozen vegetable production lines, root removal systems prepare vegetables for blanching and freezing. The machines' precision cutting reduces waste by 15-20% while maintaining vital nutrients in the final product.

4. Organic Farm Operations

Certified organic producers use specialized root cleaners that eliminate the need for chemical sanitizers. These machines incorporate food-grade brushes and purified water systems to maintain organic compliance.

5. Restaurant Supply Chains

Central kitchen facilities serving restaurant chains implement compact root removal units to process vegetables for pre-cut meal kits. The machines' adjustable settings accommodate various vegetable sizes from baby carrots to large parsnips.

6. School/Institutional Catering

Large-scale food service providers use automated root removal systems to meet high-volume vegetable preparation demands. The equipment's stainless steel construction meets food safety regulations for institutional cooking facilities.